Dr. Yuebin Guo and Team Created Lightweight Replica of the Presidential Medallion

Dr. Yuebin Guo, Henry Rutgers Distinguished Professor and Director of New Jersey Advanced Manufacturing Institute (NJAMI), and his team created a lightweight replica of the Presidential Medallion. The original cast ivy and oak leaves, along with the seal, make the Medallion heavy, causing inconvenience for significant events.

The Presidential Medallion features the university seal and an outline of the state of New Jersey with three inset garnets marking Rutgers’ presence in New Brunswick, Newark, and Camden. Both the medallion and the chain are decorated with ivy and oak leaves. The ivy represents the university, and the oak leaves represent the state tree of New Jersey, the red oak.

Dr. Guo has formed a collaborative team consisting of NJAMI PhD students, including Wenyi Liu (Project Lead), Deven Patel, and Senior Project Administrator Basily Basily, all from the Mechanical & Aerospace Department, and Makerspace Director Stephen "Skip" Carter and his student staff.

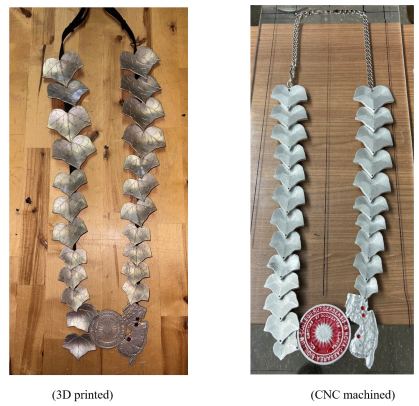

The major challenge is that no CAD or dimension data are available for making the replica. The team created CAD files of the Medallion components (i.e., 3D ivy and oak leaves, the NJ map, and the Rutgers seal with the original Latin text) based on their measurements. Then the team used 3D printing (additive manufacturing technique) and CNC milling (subtractive manufacturing technique) to make two sets of the President Medallion, a 3D printed plastic medallion (more than 90% weight reduction) with metallic finish coating and a CNC machined Aluminum medallion (70%+ weight reduction).

The plastic Medallion was printed using resin using stereolithography at the Makerspace based on NJAMI’s design. Hundreds of hours were spent printing 10 plates (i.e., the New Jersey map, the Rutgers Seal, and two leaves as one piece, or a set of leaves in various sizes). In addition, several iterations were required to finalize the sizing, coatings with acrylic paints, and method of attachment, among other details.

The aluminum Medallion was milled using a CNC machine by the Project Lead, Wenyi Liu. She created G-Code based on the CAD files using Fusion360 (a CAM software). The milling process is very challenging due to the occasional fracture of micro milling cutters and the difficulty in fixing the machined elements. More than 250 hours were estimated to make the 25 Medallion components (i.e., ivy and oak leaves, NJ map, and Rutgers seal with the original Latin), including 200+ milling hours, 5 deburring hours, and about 40 assembly hours.

Not having a high-resolution scanner at NJAMI and Makerspace was a challenge. Still, the NJAMI PhD students are very creative in generating print- and mill-ready CAD files for the Medallion components, such as the specialized historical Rutgers Seal in its original Latin.

It is essential to note that the project and process were a valuable learning experience for our student staff. It was a unique experience to create the Medallion replica in such a short time period. Students appreciated the opportunity to familiarize themselves with their machines and practice their manufacturing skills.